Clear Vision and Safety with Bosch Aerotwin Wipers

Often overlooked but essential for a safe drive: There is a noteworthy amount of know-how behind modern Bosch wiper blades with Power Protection Plus wiper rubber technology and the Longlife formula.

Despite being indispensable in the daily life of every driver, it receives very little attention. We are referring to the windshield wiper, which often goes unnoticed while quietly performing its duty. However, this lack of attention is proof of its quality. The more flawless the wiping result, the less it is noticed. There are indeed sometimes significant differences in terms of quality and, thus, the performance of this everyday helper. The design of the wiper and quality of the wiper rubber contribute to an unobstructed road view.

Customized Contact Pressure

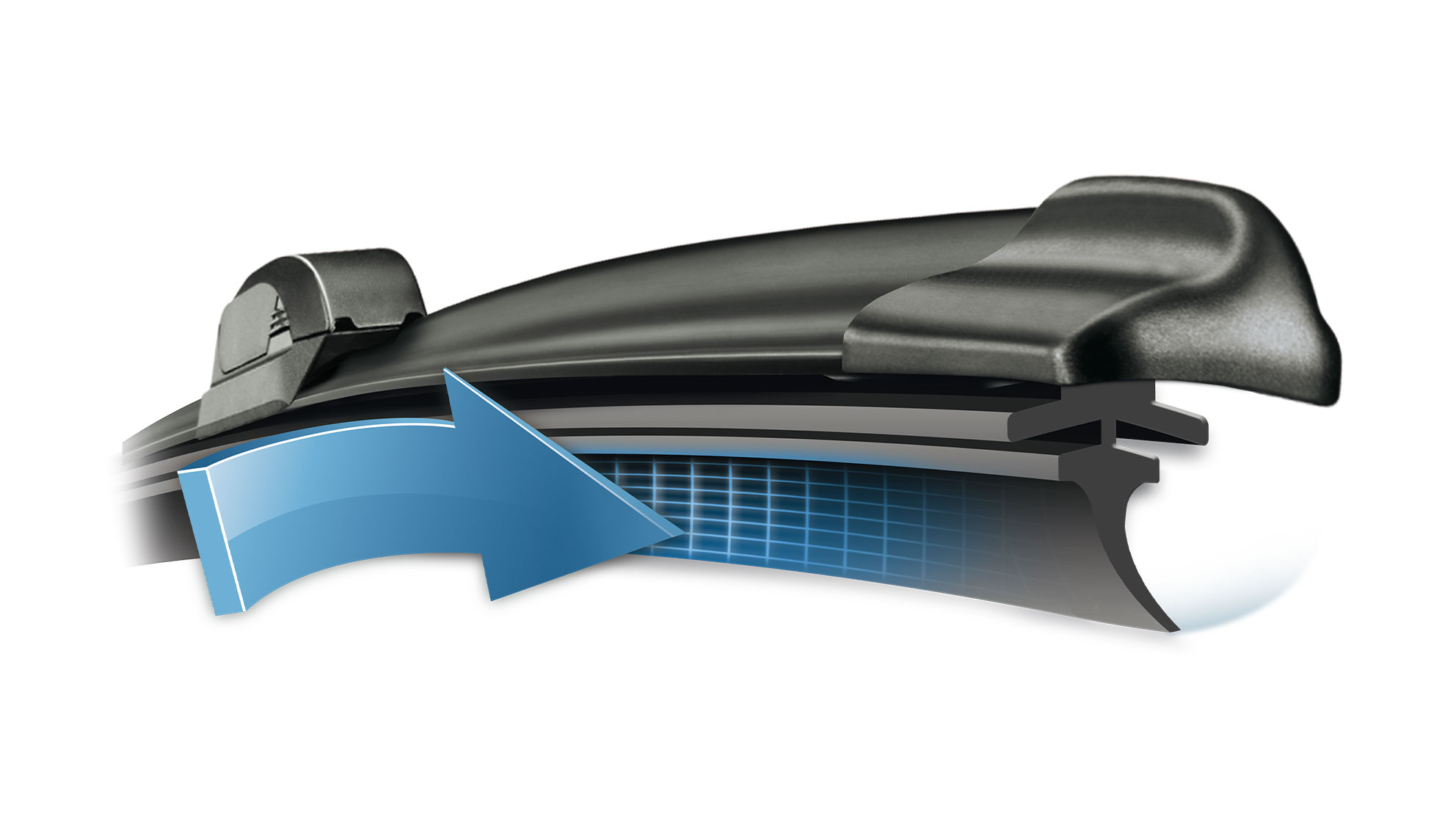

Modern generations of Bosch Aerotwin wiper blades feature a spoiler along the entire wiper length. This prevents the wiper from lifting off the windshield at higher driving speeds. In addition, Bosch uses customized Evodium spring rails that adapt to the curvature of the windshield during wiping. In combination with the wiper arm, this ensures an even contact pressure of the wiper on the windshield, resulting in an excellent wiping performance.

The Mix Matters

Bosch‘s expertise is evident in the composition of the wiper rubber, showcased through the Power Protection Plus wiper rubber technology and the Longlife formula. Power ProtectionPlus is a synthetic special blend developed by Bosch, serving as an alternative to natural rubber or polychloroprene rubber, which are no longer considered due to their controversial cultivation or environmentally harmful production and disposal. The special blend is characterized by high resistanceto aging and abrasion. An innovative wiper rubber additive, the so-called Longlife formula, makes the Aerotwin wiper blade even more robust against environmental influencesand windshield contaminants. This has the advantageof eliminating the need for additional additives such as aging protection agents, which often leave a greasy film on the windshield.

Improved Production Process

In the past, wiper rubber was crafted from a single rubber material and pressed into a mold, reminiscent of the process used in waffle-making. Bosch’s state-of-the-art technologies now employ the extrusion process. In this process, two different rubber materials are pressed out of a moulding opening. The wiper lip, which makes direct contact with the windshield, is particularly wear-resistant and made of a solid material. The wiper rubber back, on the other hand, is made of a softer material, allowing the wiper to turn over flexibly and without noise during direction changes.

The BOSCH Success Secret

After extrusion, a special thermoplastic, i.e., a type of powder coating, is sprayed onto the wiper rubber and vulcanized in a special salt bath. In this chemical reaction, through the application of high temperatures, the rubber is made dimensionally stable. This patented coating enhances the wiper rubber‘s resistance to wear and abrasion while also providing exceptional heat resistance. Additionally, it guarantees a smoother glide of the wiper over the windshield, eliminating any unpleasant squeaking noises.

Upon closer inspection, the seemingly inconspicuous everyday helper reveals itself as a sophisticated technological product. With the benefits of Power Protection Plus, the Longlife formula, and patented coating, Bosch Aerotwin wiper blades deliver an excellent and long-lasting wiping performance.

Further information on the topic in the video

5 Advantages

of Power Protection Plus Wiper Rubber Technology and Longlife Formula: